Cobots: Revolutionizing Human-Robot Collaboration Cobots, or collaborative robots, are rapidly changing the landscape of modern manufacturing and beyond. Unlike traditional industrial robots that operate behind safety cages, cobots are designed...

Cobots: Revolutionizing Human-Robot Collaboration

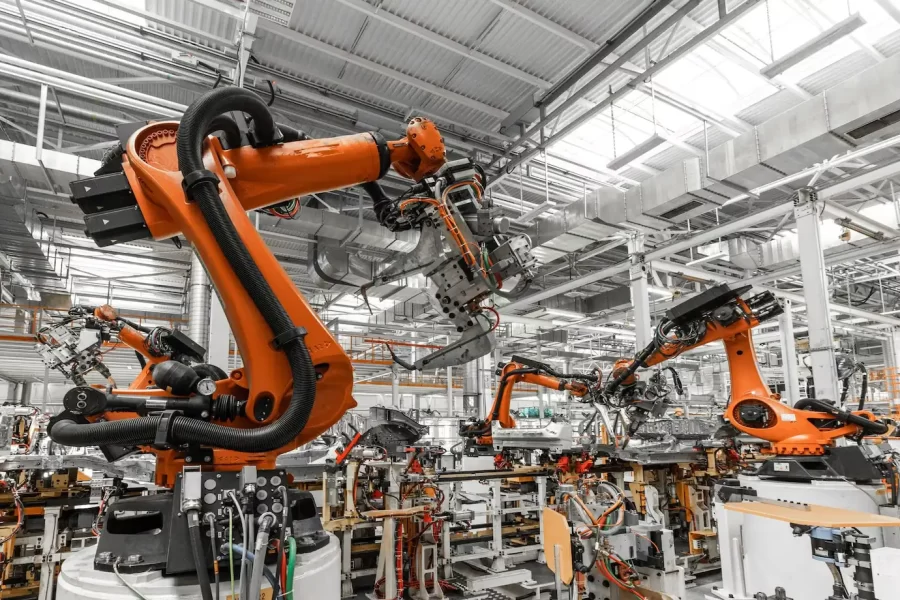

Cobots, or collaborative robots, are rapidly changing the landscape of modern manufacturing and beyond. Unlike traditional industrial robots that operate behind safety cages, cobots are designed to work directly alongside humans, making automation more accessible and flexible.

What is a Cobot and How Do They Work?

The most fundamental question when discussing these machines is: What defines a cobot? A cobot is a robot specifically designed to interact with humans in a shared workspace or collaborate directly on a task. Their primary characteristic is their ability to operate safely near or with human operators without requiring extensive safety guarding.

So, how do cobots differ from industrial robots? The key distinction lies in their safety features and design philosophy:

- Safety Features: Cobots incorporate advanced safety mechanisms such as force and torque sensors that allow them to detect collisions and stop or slow down immediately. They often have rounded edges, lighter materials, and slower operating speeds compared to their industrial counterparts.

- Ease of Programming: Many cobots feature intuitive programming interfaces, including “lead-through” programming where an operator physically guides the robot arm to teach it a task. This drastically reduces the need for complex coding expertise.

- Flexibility and Adaptability: Cobots are typically smaller and lighter, making them easier to redeploy for different tasks or in various locations within a facility.

- Human-Robot Interaction: They are built for seamless integration into human workflows, enhancing productivity rather than simply replacing human labor.

Pondering how cobots ensure human safety? Their integrated safety systems, including collision detection, power and force limiting, and safe speed monitoring, are paramount. These features allow them to operate without traditional barriers, fostering a truly collaborative environment.

Where Are Cobots Used and What Are Their Benefits?

Cobots are finding their way into an increasing number of industries and applications due to their unique capabilities. So, what are the most common applications for cobots? and what advantages do they offer businesses?

Here are some primary application areas for cobots:

- Assembly: Cobots excel at delicate and repetitive assembly tasks, working alongside human operators to pick, place, and fasten components with precision. This is particularly common in electronics and automotive sub-assembly.

- Machine Tending: They can efficiently load and unload parts from CNC machines, injection molding machines, and other equipment, freeing human workers for more complex or supervisory roles.

- Packaging and Palletizing: Cobots can quickly and accurately pick products, place them into boxes, and stack boxes onto pallets, reducing manual strain and increasing throughput in logistics and manufacturing.

- Quality Inspection: Equipped with vision systems, cobots can perform detailed quality checks, identifying defects or inconsistencies with high accuracy and consistency.

- Polishing and Finishing: For tasks requiring consistent pressure and movement, cobots can apply polishes, glues, or perform sanding, ensuring uniform product quality.

- Material Handling: Lighter material handling tasks, such as moving small parts between workstations, are ideal for cobots.

What industries are benefiting most from cobots? Industries like electronics manufacturing, automotive, consumer goods, medical devices, and food & beverage are rapidly adopting cobot technology.

The advantages offered by cobots are compelling. What are the key benefits of integrating cobots into a workflow?

- Increased Productivity: By automating repetitive and physically demanding tasks, cobots allow human workers to focus on higher-value, more complex activities, leading to overall efficiency gains.

- Enhanced Flexibility: Their ease of deployment and reprogramming makes them highly adaptable to changing production demands and product variations.

- Improved Ergonomics and Safety: Cobots can take over tasks that are ergonomically challenging or pose safety risks to human operators, reducing injuries and improving working conditions.

- Lower Initial Investment: Compared to larger industrial robots that require significant infrastructure changes, cobots often have a lower upfront cost and quicker ROI.

- Space Saving: Their ability to work safely without large enclosures saves valuable floor space in manufacturing facilities.

- Addressing Labor Shortages: In an era of skilled labor shortages, cobots can augment the existing workforce, allowing companies to meet production targets.

What Does the Future Hold for Cobots and Collaborative Automation?

The field of collaborative robotics is evolving rapidly, driven by advancements in artificial intelligence and sensor technology. So, how will AI impact the future of cobots?

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is making cobots even more intelligent and autonomous. AI-powered cobots can learn from their environment, adapt to new tasks more quickly, and make more complex decisions. This will enable them to perform a wider range of tasks with even less human intervention, while maintaining their collaborative nature.

Looking ahead, we can anticipate several key developments in cobot technology:

- More Advanced Perception: Cobots will have enhanced vision and haptic feedback capabilities, allowing them to handle more delicate and complex materials, even in unstructured environments.

- Smarter Decision-Making: With improved AI, cobots will be able to make more nuanced decisions in real-time, adapting to unexpected situations or variations in materials.

- Seamless Human-Robot Interaction: Natural language processing and advanced gesture recognition will make communication with cobots even more intuitive and efficient.

- Expansion into New Sectors: Expect to see cobots increasingly in areas like healthcare (assisting nurses or lab technicians), retail (stocking shelves), and even agriculture (precision farming tasks).

- Mobile Cobots: The combination of collaborative arms with mobile bases will create highly flexible robots capable of moving autonomously throughout a facility to perform various tasks.

However, as cobots become more integrated into our workplaces, new considerations arise. Cobots represent a significant step forward in automation, bridging the gap between fully autonomous machines and human workers. Their ability to work collaboratively offers a flexible, safe, and efficient path to increased productivity and innovation across numerous industries.