In industrial production processes, efficiency and speed have always been top priorities. In recent years, robotic CNC tending systems have emerged as a significant solution to meet this demand. While CNC machines provide the most efficient results in tasks requiring high precision and automation, uninterrupted production becomes possible with the help of robots that keep these machines running continuously. However, achieving 24/7 production requires the integration of the right systems and optimized robotic solutions. In this article, we will delve into topics such as robots for CNC machines, 24/7 production systems, and CNC tending robotic systems. We will also discuss the advantages offered by robotic production systems, features that enhance efficiency, and future developments.

What is a Robotic CNC Tending System and How Does It Work?

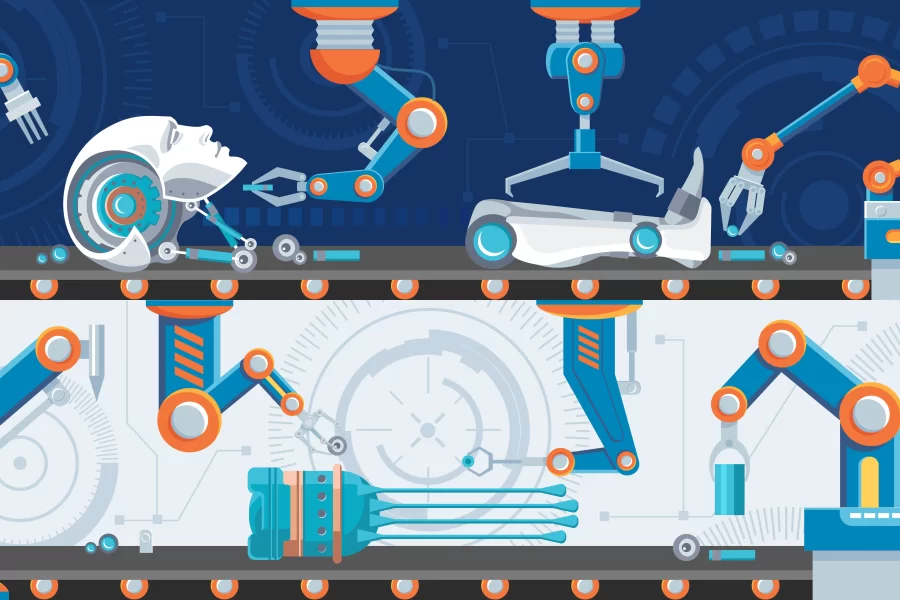

Robotic CNC tending systems are robotic technologies that automatically pick and place parts, performing loading and unloading operations for CNC machines. These systems reduce the need for manual labor, thereby speeding up the production process and increasing efficiency. Robots for CNC machines are typically equipped with a robotic arm, sensors, and control software. These systems work in harmony with each machine on the production line to ensure a continuous manufacturing process.

When a robot performs a part loading operation, the CNC machine begins processing. Once the machine completes its task, the robot re-engages to place a new part. This process, which is at the heart of CNC tending efficiency systems, minimizes the human factor and reduces error rates. As a result, production continues uninterrupted, allowing for 24/7 production.

Advantages of Robotic CNC Tending Systems for Uninterrupted Production

Uninterrupted production robots significantly boost efficiency in industrial manufacturing systems. Human errors, breaks, and maintenance issues often lead to substantial production losses in traditional manufacturing processes. However, with robotic CNC tending systems, such interruptions are eliminated.

Robots ensure continuous production, allowing machines to operate for much longer periods. With 24/7 production systems, businesses can manufacture without any downtime, which increases production capacity. Furthermore, robots guarantee not only speed but also consistent quality. This results in more uniform and higher-quality products.

Another advantage is that robots don’t experience fatigue like humans do. Human operators require rest after a certain period, but robots can work tirelessly. This feature is a huge advantage, especially in situations requiring high-volume production.

Speed and Efficiency Performance of Robots in CNC Tending Systems

Robotic production systems are generally designed for high-speed operation. Robots that work in conjunction with CNC machines ensure quick loading and unloading of parts. This speed shortens production time while also increasing production volume.

The speed performance of robots can be further optimized with correct software integrations and mechanical design. CNC tending robotic systems complete each operation within milliseconds, significantly boosting efficiency. Moreover, robots can operate at very high speeds without losing accuracy, eliminating the possibility of human operator error.

This system’s speed and efficiency-enhancing aspect is also machine-to-machine integration. A robot can quickly move from one CNC machine after it completes a task to the next. This transition process prevents any interruptions in the production line and ensures a smooth production flow.

Reducing the Human Factor and Operator Safety with Robotic CNC Tending

Robotic CNC tending systems significantly reduce the human factor. This offers a major advantage, especially in repetitive, time-consuming, and physically demanding tasks. Humans can get tired from performing the same operation for extended periods, but robots do not experience such fatigue.

Additionally, robots can be used in hazardous jobs. CNC machines with operations that sometimes involve very high temperatures or cutting tools, can incorporate robots into these tasks to increase operator safety. Automation for CNC machines prevents humans from entering risky environments and creates a safer production environment.

The use of robots reduces workplace accidents and health problems. CNC tending systems’ robot speed and efficiency performance also improves operators’ working conditions.

Reducing Process Times and Production Time with Robotic CNC Tending Systems

When a robotic CNC tending system is used, process times are significantly reduced. In traditional methods, an operator loading a part and starting the machine can be quite time-consuming. However, robots can complete this operation within a few seconds.

Robotic production processes work faster and more efficiently, so production times are dramatically decreased. This is a huge advantage, especially in time-sensitive projects. Uninterrupted production robots optimize the overall production process by accelerating each step.

These fast process times allow factories to get more work done and enable businesses to increase capacity. Furthermore, robots’ ability to complete tasks quickly also offers the opportunity to provide customers with shorter delivery times.

Quality Control in High-Volume Production with Robotic CNC Tending Systems

Quality control in high-volume production has always been a challenging process. However, CNC tending robotic systems offer a significant solution to ensure quality in the production process. Robots operate with the same precision in every operation, ensuring consistency for each part.

Thanks to robots for CNC machines, quality control processes also become more efficient. Robots can be equipped with automatic sensors and camera systems. These sensors ensure that parts are processed correctly, and if any error occurs, the production process is immediately stopped. These automatic control mechanisms minimize production errors and consistently maintain high quality.

Advanced Software and Hardware Integrations for CNC Tending Systems

Effective operation of robotic CNC tending systems requires proper software and hardware integrations. These systems are supported not only by mechanical components but also by high-performance software.

Advanced software enables robots to work in harmony with CNC machines. This software makes decisions about which operations the robot will perform, at what speed it will operate, and when to load which part. Additionally, advanced analysis tools are used for continuous monitoring and optimization of robots.

Software integrations can further accelerate production processes and ensure higher efficiency. CNC tending robotic systems become more effective with the right software support.

High-Performance Production with Robotic CNC Tending: Challenges and Solutions

Although robotic CNC tending systems offer many advantages, the application of these technologies also brings some challenges. The main challenges include high costs, potential problems in system integration, and the adaptation process for employees.

However, these challenges can be overcome. Automation solutions for CNC machines are becoming more affordable every day. Also, with a trained workforce, the transition to robot systems becomes smoother.

For high-performance production, proper programming and continuous maintenance of robots are crucial. At this point, the advanced features of robotic technology help overcome the challenges.

Maintenance and Monitoring of Robotic CNC Tending Systems for Uninterrupted Production

Once a robotic CNC tending system is installed, its maintenance and monitoring are very important. Regular maintenance is necessary for robots to operate continuously. Additionally, system performance should be continuously monitored, and any malfunctions should be addressed promptly.

Uninterrupted production robots require periodic maintenance to preserve operational efficiency. These maintenance tasks include checking the robot’s moving parts, performing software updates, and calibrating sensors.

System monitoring software can track robot performance in real-time and predict maintenance needs in advance.

The Future of Robotic CNC Tending Technologies and Industry Developments

The future of robotic CNC tending technologies seems to be shaped by smarter, faster, and safer systems. Next-generation robots will have greater autonomy, and their learning and adaptation processes will improve.

CNC tending robotic systems will also become more efficient and flexible. This will allow them to work harmoniously even in different types of production lines. Furthermore, with Industry 4.0 technologies, robots will perform more advanced data analyses to make processes even more efficient.

Robots are expected to be integrated into more production processes and used in broader areas. This will make industrial production processes faster, more efficient, and more sustainable.