Contact

Aerobic Genius Series

- SORA ROBOTIC

- Aerobic Genius Series

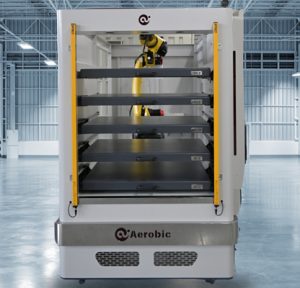

Aerobic Genius Series – Smart CNC Loading & Unloading Cell

Sora Robotic’s Aerobic Genius Series fully automates the loading and unloading processes of your CNC machines, creating Industry 4.0 compliant production environments. This system increases efficiency while minimizing operator touch, reducing the risk of errors, and ensuring uninterrupted production flow.

Aerobic Genius Series Technical Specifications & Cell Data

Cell Dimensions (W × D × H): 1290 × 2630 × 2200 mm

Maximum Workpiece Height: 130 mm

Supply Voltage: 380 V (three-phase)

Cell Weight: Approx. 1500 kg

Payload Capacity: 12 – 35 kg

Aerobic Genius Series Operating Principle & System Functions

Aerobic Genius takes the raw parts placed by the operator, transfers them to the CNC machine, retrieves the processed part, and automatically maintains this cycle.

The system supports automatic recipe (parameter) setting for different sized parts — no manual intervention is required.

Robotic arms are equipped with special grippers or vacuum systems, moving with high speed and precision.

The cell works in full synchronization with the CNC machines; delays and waiting times are minimized.

Production processes are monitored via data-linked modules, errors are instantly detected, and retrospective analysis can be performed.

Why Aerobic Genius?

7/24 Uninterrupted Production: It can operate continuously with the automatic feeding system; production continues even outside of shifts.

High Precision & Quality: It prevents out-of-tolerance production by loading and unloading parts into the CNC machine with great accuracy.

Shorter Cycle Times: Processing time can be significantly reduced through workflow optimization.

Operator Safety & Ergonomics: It reduces the risk of work accidents by taking over heavy and repetitive tasks.

Smart Monitoring & Industry 4.0 Compliance: Data-driven control, performance monitoring, and predictive maintenance can be performed thanks to sensors and software.

High Adaptability: It can be easily integrated with different machine types and parts.

Aerobic Genius Series Application Areas

CNC Milling / Lathe / Machining Centers: Part loading & unloading automation

SMEs and Medium-Sized Workshops: Businesses looking to increase production competitiveness with lower-cost automation

Multi-Part Series Production: Synchronized processing of different types and sizes of parts along the line